Applied Wood Science & Technology - Dr. Oliver Kläusler

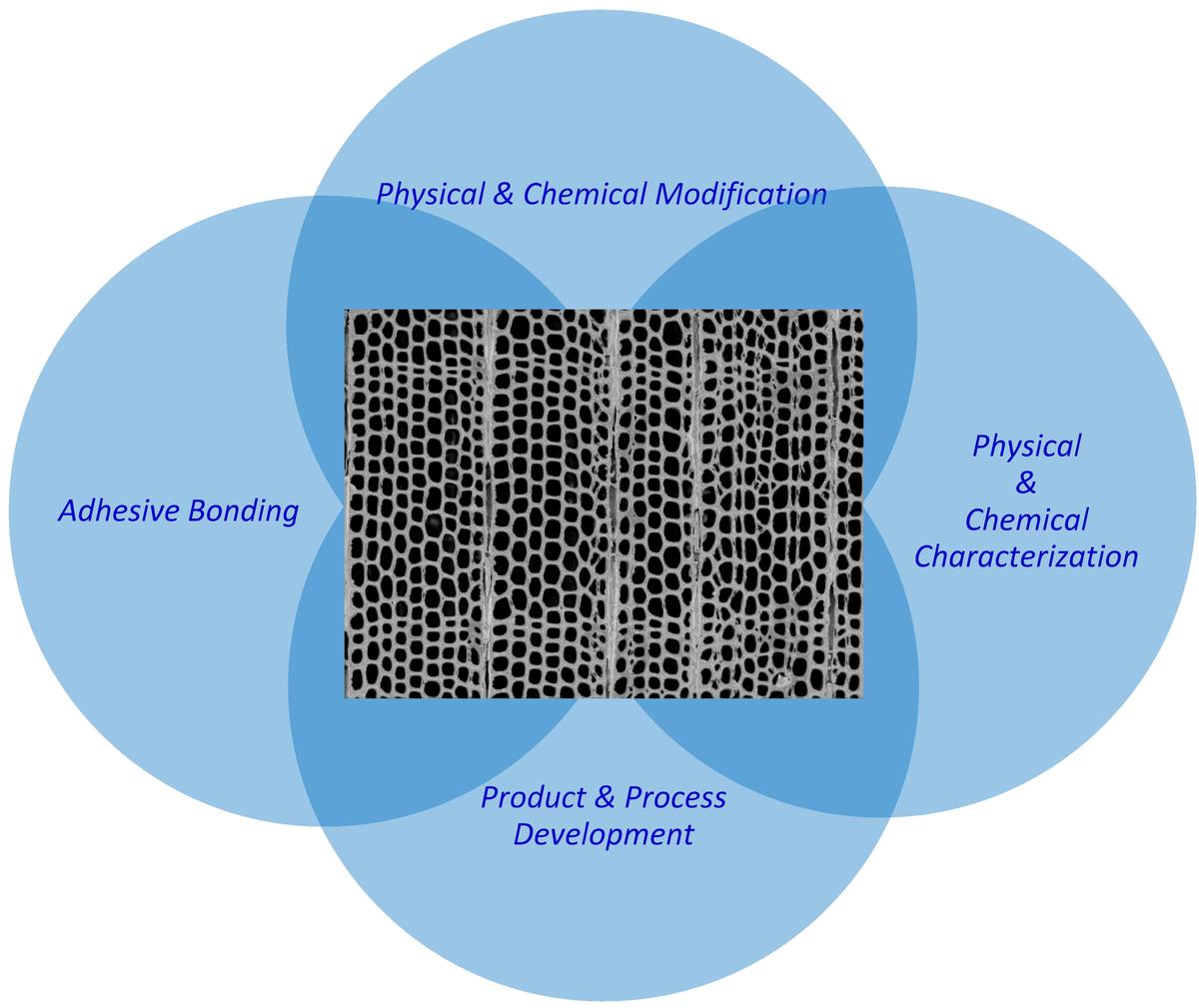

The core activity of the group “Applied Wood Science and Technology” is the wood related technology transfer from science into practice.

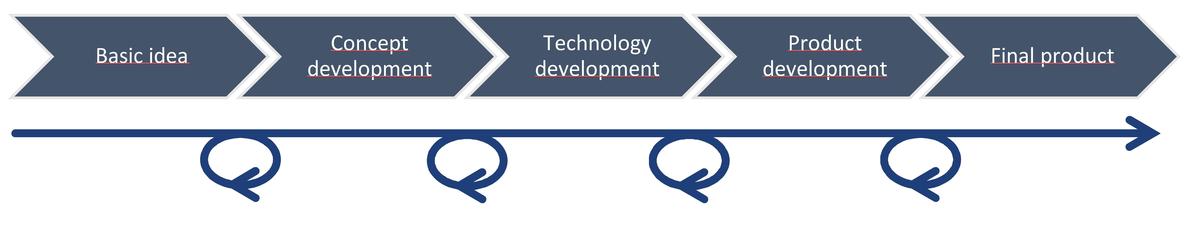

New technological approaches have to go a long way before they can successfully be implemented into the environment of private enterprises. Moreover, this is just the first stage of a challenging process, which finally leads to the market entry of a new product.

We are dedicated to developing new concepts for coping with new wood related technological challenges. This also comprises the upscaling of innovative processes from lab scale to pilot scale as well as the accordant ramp-up support on-site.

As a cornerstone of our work, we foster a reliable cooperation with partners from private enterprises, scientific institutions, foundations and associations. This allows for providing essential expertise in all stages of the innovation process, from basic ideas to final product optimizations.

During this process several optimization loops should be taken into account, since creative processes hardly ever go linear. This accounts for incremental innovations as well as for radical ones. However, the second and most important cornerstone of our group is the complementary experience of the group members in their specific fields.

Currently we run various projects which are funded by CTI, Gebert Rüf Foundation, and SEED or via direct financial contributions from private enterprises.

Our core fields of expertise

1) Adhesive bonding

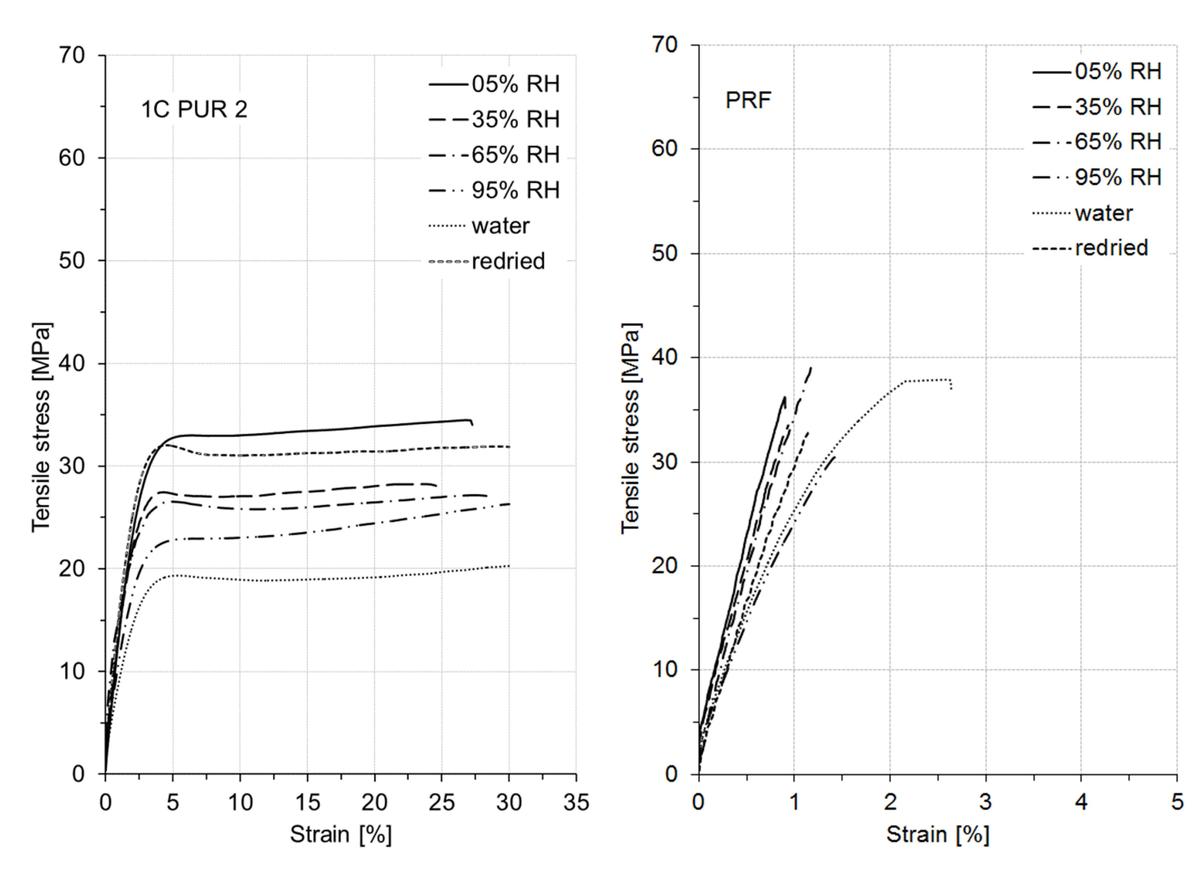

- Various bonding systems and adhesion promoters

- Characterization of interactions between adherend and adhesive polymer

- Mechanical testing of polymer films or bonded samples under varied ambient conditions

- Manufacturing and characterization of adhesive polymer films

No database information available

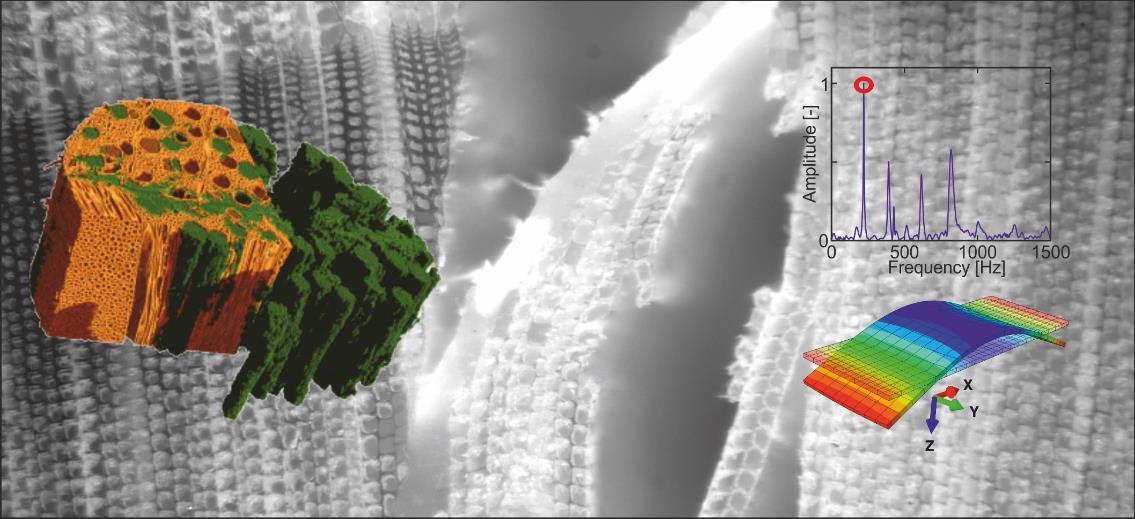

2) Physical characterization techniques

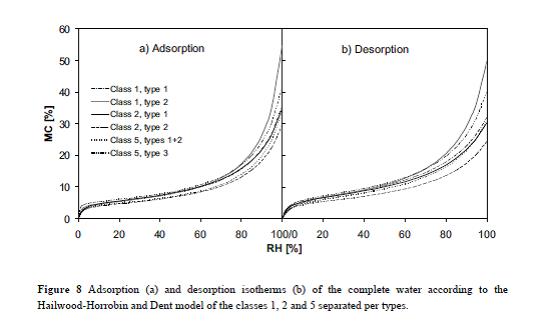

- Sorption/desorption (DVS, climate chambers)

- Diffusion (dry cup / wet cup)

- Heat conduction (incl. thermal diffusivity and heat capacity)

- Thermo-gravimetric analysis

- Contact angle measurements

- Nondestructive testing (Ultrasound, eigenfrequency, etc.)

- DSC (determination of TG)

- Single-flame burning test

- Color measurements

- Artificial weathering (QUV, UV)

No database information available

3) Mechanical testing by means of universal testing machines

- Universal testing machines for standard testing protocols and modified testing procedures

- Micro tensile stage

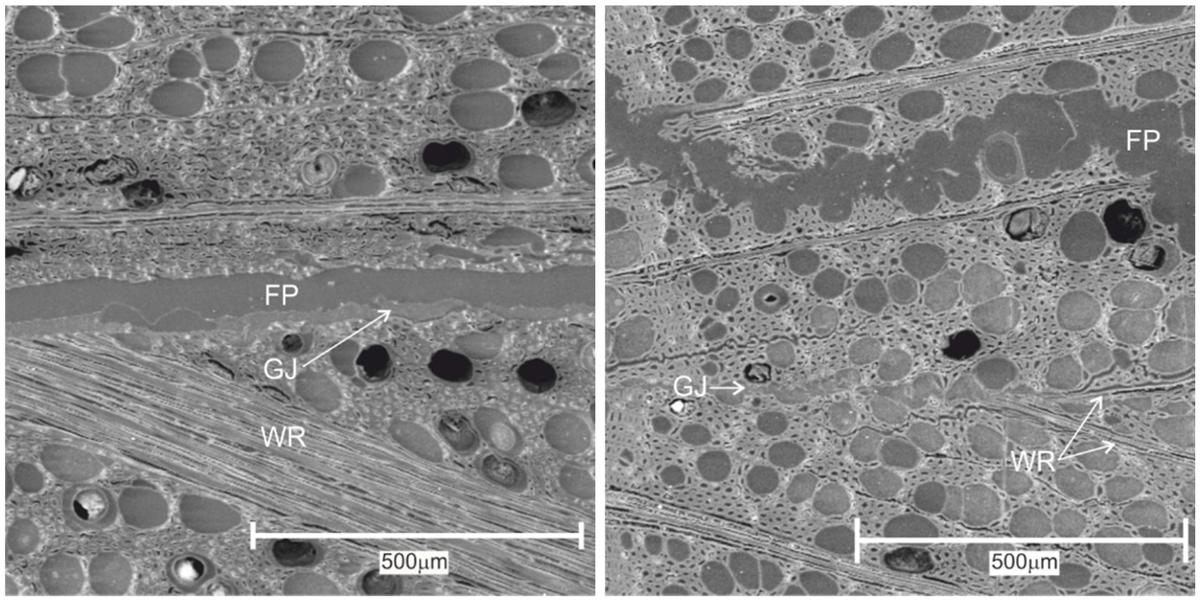

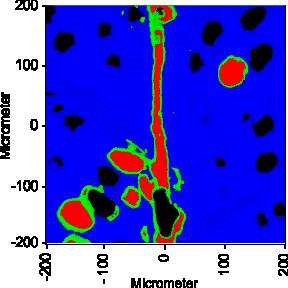

4) Microscopy techniques

- ESEM, SEM / EDX

- Reflected-light and transmitted-light microscopy

- AFM

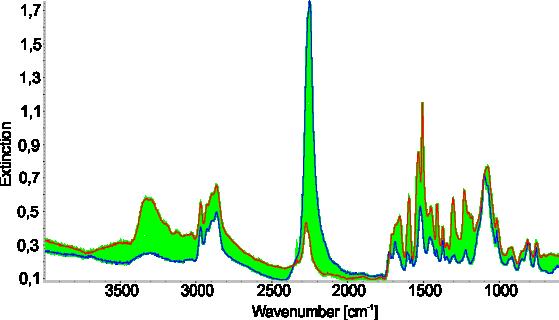

5) Chemical characterization techniques

- Spectroscopic techniques (FTIR, UV, Raman)

- Wet chemistry

6) Processing technology

- Adaptation of devices and processes within the scope of upscaling processes

- Development of concepts and processes in consideration with new technical standards and environmental regulations

- Design of pilot processes for physical or chemical wood modification