Research overview

Find out more about the six research areas we are working on.

A wide number of projects in our research group aim at revealing the fundamental mechanisms of corrosion.

Our primary interest are corrosion phenomena in the construction and energy sectors. This includes the mechanisms of corrosion initiation and propagation of reinforcing steel in concrete, pipe steel in soil, steel structures, additively manufactured components, radioactive waste disposal, etc.

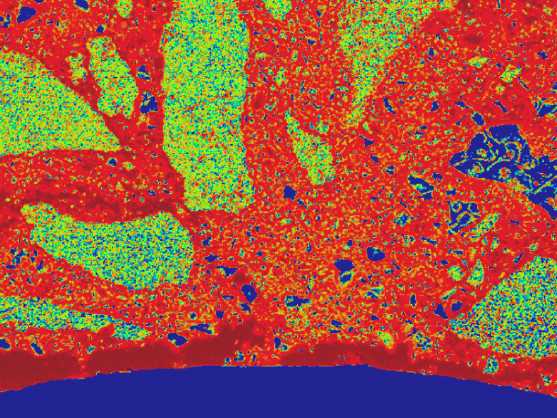

We use experimental and computational methods. We combine electrochemistry with microcopy, surface science and, thanks to collaborations, advanced characterization and imaging methods such as neutron and X-ray imaging, Fib-SEM nanotomography, and synchrotron based analytical techniques.

Various projects in our research group aim at laying the theoretical basis for innovations in the field of inspection, non-destructive testing (NDT), condition assessment, sensors and monitoring.

Our primary interest is to advance knowledge in order to allow for more reliable and accurate diagnoses of the condition of civil engineering structures. The focus lies on diagnosing the corrosion condition, assessing the risk for corrosion, and forecasting the future performance.

We strive to promote the transfer of technology from science to industry. Our scientific work led to various collaborations with industrial partners, to patents filed and to a spinoff (external page DuraMon).

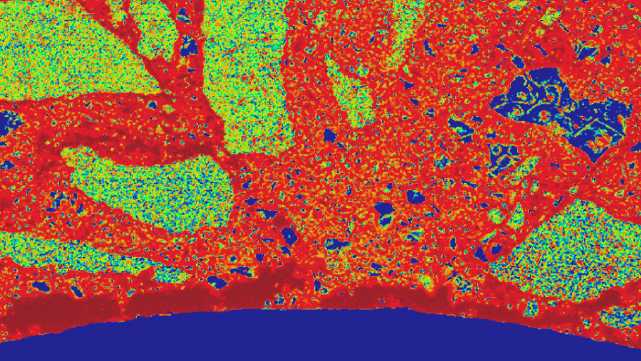

Recognizing that the presence of moisture at the metal surface is crucial for corrosion processes to occur, we have a number of projects aiming at improving the quantitative prediction of moisture at the steel-porous medium interface.

We use different computational methods to model moisture transport in porous media (primarily concrete and soil) under constant and dynamic exposure conditions. We use experimental methods for material characterization, determining model input parameters, and for producing well-controlled experiments for validation of the numerical models.

The field of moisture transport and retention in porous media in our research group is led by Dr. Zhidong Zhang.

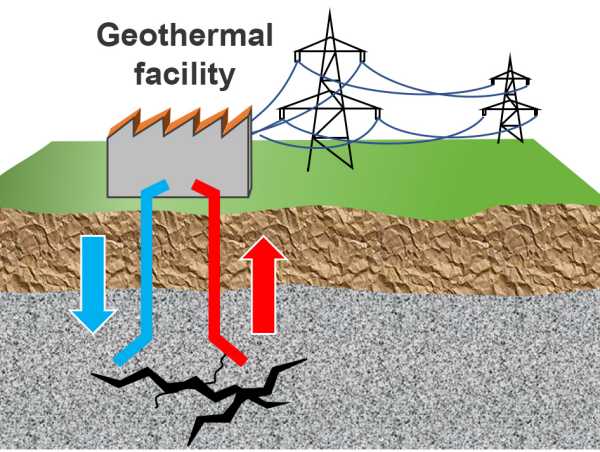

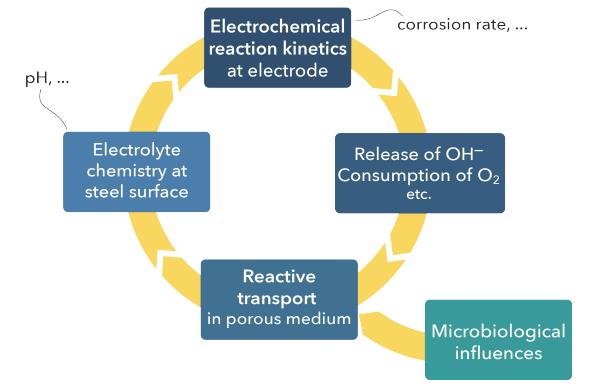

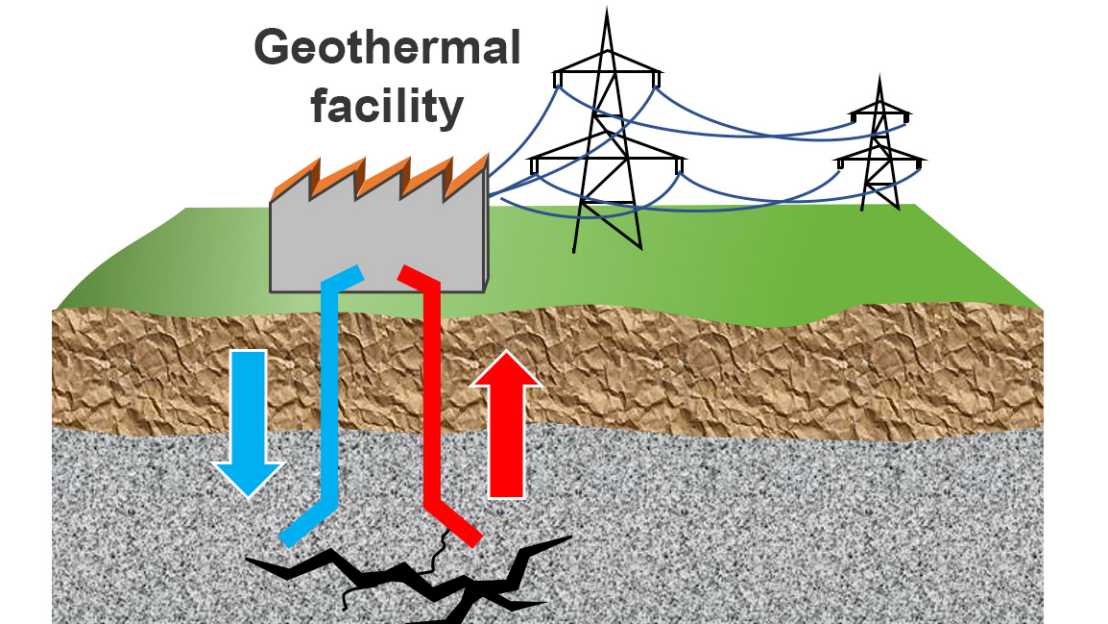

A wide number of projects in our research group aim at improving the numerical modeling of reactive transport processes and coupled corrosion processes occurring at a metal surrounded by a porous medium. This is an important scientific problem with applications to various practical problems, including corrosion of steel in concrete (bridges, buildings, …), corrosion of steel in soil (buried pipes, geotechnical structures, archaeological artefacts) or corrosion related to radioactive waste disposal.

Our primary goal is to study the coupling between reactive transport processes occurring in the porous, chemically reactive medium and electrochemical processes occurring at the embedded metal.

We use different modeling approaches and seek to produce experimental data for the purpose of validation of individual components of complex and coupled models.

Corrosion not only impacts economy and safety, but can also have severe consequences for the environment. Examples are failures of pipes and tanks that may release harmful substances into the environment or the consumption of resources upon premature repair of infrastructures.

We aim to lay the scientific basis in order to forecast the performance of structures over their lifetime and to thus enable the quantification of service life costs and environmental footprint. We develop concepts, test methods and models to support engineers in the planning stage of new structures, e.g. with respect to material selection to ensure durability while optimizing costs and minimizing the impact on environment. Such guidance is becoming increasingly important in a world of increasing complexity in terms of variety of available materials and construction methods (additive manufacturing, digital construction) as well as regulative boundary conditions.

Additionally, we develop concepts, test methods and models to support decision takers at the infrastructure management level, e.g. to allow for “predictive maintenance”.

To ensure technology transfer, we collaborate with industrial partners and national and international authorities and agencies. Moreover, we are engaged in standardization.

View the project description.