Corrosion of steel in geothermal power plants in Switzerland

Responsible: Ana Vallejo Vitaller

Collaboration/Funding: SCCER-SoE Swiss Competence Center for Energy Research – Supply of Electricity (external page http://www.sccer-soe.ch/en/home/)

Background

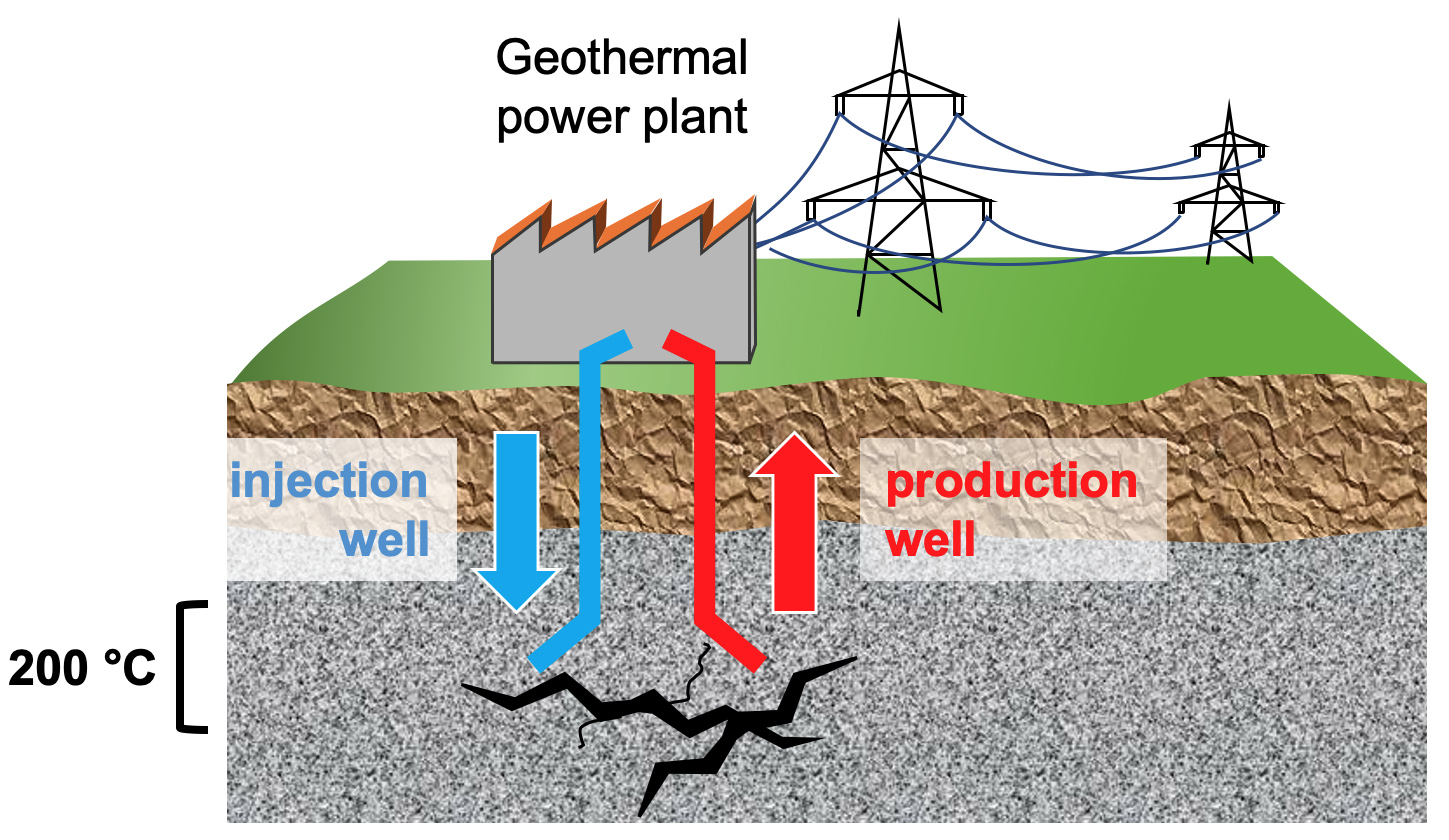

The co-generation of electric power and district heating from geothermal resources might play a significant role in the future carbon-free energy systems worldwide. Whereas geothermal energy presents various advantages, there are numerous technical challenges that need to be addressed related to the accessibility, exploitation, and long-term durability of materials. In this regard, the selection of materials for the well casings, heat exchangers, or pipes with feasible economic impact is crucial to operate a geothermal power plant in service for more than 30 years. In Switzerland, deep geothermal energy can give a promising contribution to the future energy mix. In 2011, the ambitious plan "Energy strategy 2050" was approved and will require about 4–5 TWh/yr from deep geothermal energy by 2050, representing 7.5% of the projected annual power need.

Aims and objectives

The main aim of this project was to improve the scientific understanding of corrosion processes that might occur in geothermal energy power plants in Switzerland in order to achieve a long-term and safe operation with minimum maintenance

Methodology

A multi-instrument experimental setup was designed, installed, and calibrated for material corrosion testing purposes. This setup allowed investigation in the pressure range from 1 to 50 bar and at temperatures from 90 to 200 °C. It mainly consists of an electrochemical cell (i.e., a metallic autoclave with a three-electrode configuration), a ZrO2-based solid-state pH electrode, and devices to control the temperature and stirring of the aqueous solution. A particular focus was on validating the correctness of the measurements and to exclude error measurements that may arise from e.g. ground loops in a complex system consisting of various interfaces and devices. For a more detailed description of the setup, it is referred to the section laboratory equipment and to the literature indicated below.

With this setup, the corrosiveness of two fluids, representative of optimal geothermal conditions in Switzerland, was assessed employing two experimental setups that allowed performing electrochemical measurements (at 100 and 200 °C). Furthermore, the influence of the operation and maintenance of geothermal power plants on the degradation of API L80 steel was studied, namely temporary changes in temperature and oxygen concentration, which may occur during maintenance interruptions or shutdowns of a geothermal power plant. It was found that these conditions may significantly influence the corrosion behavior and thus need to be considered in the design and operation of geothermal facilities. Further information can be found in the publications indicated below.

Publications

- Vitaller AV, Angst U. Elsener B. A setup for electrochemical corrosion testing at elevated temperature and pressure.

Measurement 155 (2020) 107537. external page doi:10.1016/j.measurement.2020.107537 - Vitaller AV, Angst U, Elsener B. Corrosion behaviour of L80 steel grade in geothermal power plants in Switzerland.

Metals 9 (2019) 331. external page Open access: doi:10.3390/met9030331 - Vitaller AV, Angst U. Elsener B. Laboratory tests simulating corrosion in geothermal power plants – influence of service conditions.

Geothermal Energy: Science, Society, and Technology 8 (2020) external page doi.org/10.1186/s40517-020-00163-y - Vitaller AV. Corrosion studies of steel in geothermal power plants in Switzerland. PhD thesis. DISS. ETH NO. 26645. ETH Zurich, 2020.