Digital Casting Systems

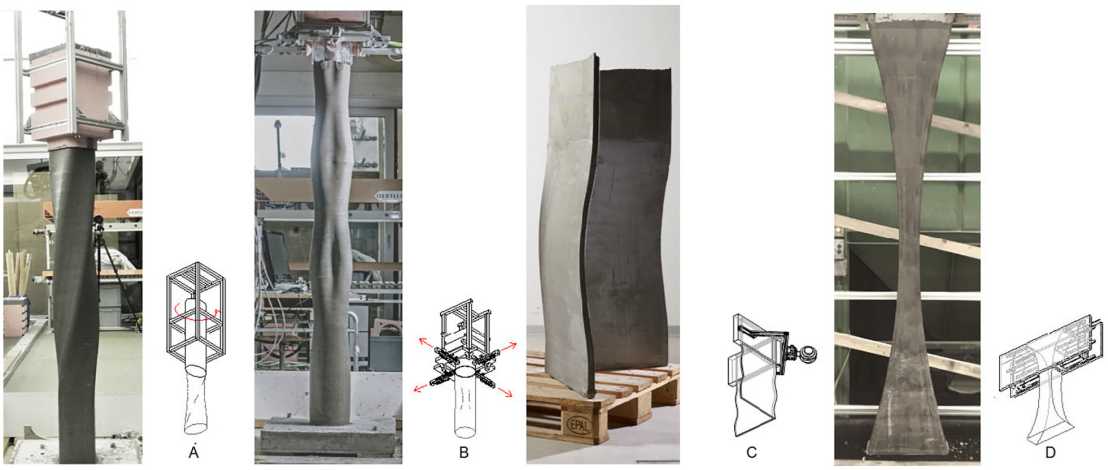

While most of the Digital Concrete community has been focused on layered extrusion technologies such as 3D concrete printing, several years ago Gramazio Kohler Research, Physical Chemistry of Building Materials and Computational Physics of Engineering Materials began a collaboration known as external page Smart Dynamic Casting, in which custom concrete elements were shaped by scaling down the process of slip forming and digitally controlling it, ultimately used in the production of bespoke façade mullions in the DFAB House. The set control material strategy used in this process has since been adapted for other casting processes in which controlled strength buildup is critical, such as the Eggshell process, which was used to create the base of the FutureTree pavilion. In this invited article published in the Cement and Concrete Research Digital Concrete 2020 special edition, Dr. Ena Lloret-Fritschi and others detail the history of the development of these processes and give perspectives on future work for Digital Casting Systems.

Read the full paper external page here:

E. Lloret-Fritschi, T. Wangler, L. Gebhard, J. Mata-Falcón, S. Mantellato, F. Scotto, ..., R. Flatt, From Smart Dynamic Casting to a growing family of Digital Casting Systems, Cement Concr. Res., 134 (2020), p. 106071